APPLICATIONS

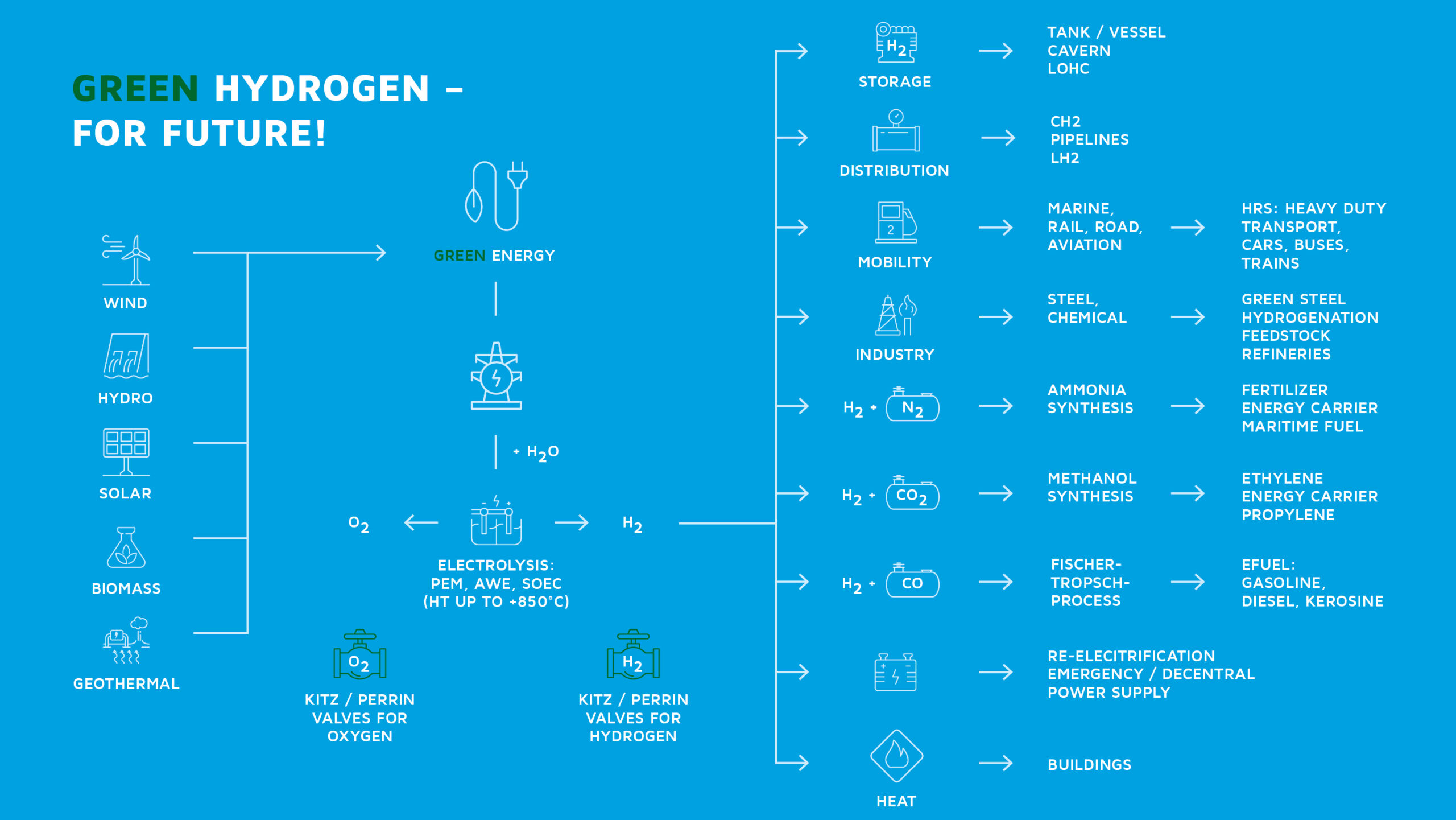

Clean Energy

Applications in different areas:

-

Mobility

-

Storage and Transport

-

Green Steel/DRI

-

E-fuels synthesis and derivates (ammonia, methanol, …)

Chemical and Petrochemical

Examples for Remington Applications in Chemical and in Petrochemical:

-

Paints

-

Adhesives

-

Polyethylen/Polypropylen – according to the following licenses Novolen®, Spheripol® (Basell), Borstar® (Borealis), Unipol®

-

PTA

-

MDI/TDI (Methylendiphenyldiisocyanat / Toluoldiisocyanat)

-

PA12

-

Ethylenoxide

-

Silicone

-

Phosgene

-

Coal gasification

-

Delayed coking

Storage technology

Examples for Remington applications in storage technology:

-

Storage of oil and gases in caverns

LNG,gases and loading arm technology

Examples for Remington applications for LNG and gases:

-

ERS (Emergency release Systems)

-

LNG

-

Dry Gases and cryogenic applications

-

Oxygen

-

Coal gasification

-

Helium

-

Nitrogen

-

Gas refinery

Steel and aluminum industry

Examples of Remington applications in the steel industry and in mechanical engineering:

-

Green Steel – DRI (Direct Reduced Iron >700°C

-

Coal injection for steel productioning

-

Iron ore production (HDRI – Hot iron reduction)

-

Decoking

-

Loading arm technology

Power Plants

Advantages of Remington ball valves in power plant technology

Examples of Remington nuclear and power plant applications are:

-

Nuclear facilities

-

KTA approval for use in nuclear plants

-

DeNOx systems

-

Ball valves for the REA

-

Ball valves in steam and water circuits

-

Ball valves in conventional or fluidized bed combustion

-

Ball valves in tank systems

-

Preparation of preliminary test documents and calculations (e.g. seismic calculations) by our own team of qualified designers and specially trained staff in the documentation department.

-

By using various metal coating materials (hardfacing) and using Remington’s internal technology and application facility, this ball valve design can also be easily adapted to find solutions for handling abrasive and solids under high pressure as well as high temperatures commonly found in power plants and the like.

-

Seat systems with options for soft, hard and metal seals enable Remington ball valves to be used under the utmost demanding conditions that can be found in power plant applications.

-

By using different metallic materials for the housing and internal parts (carbon steels, stainless steels, duplex steels, Hastelloy, Monel, Inconel, titanium or similar), the ball valves are suitable for shutting off a wide-range of media in power plants.