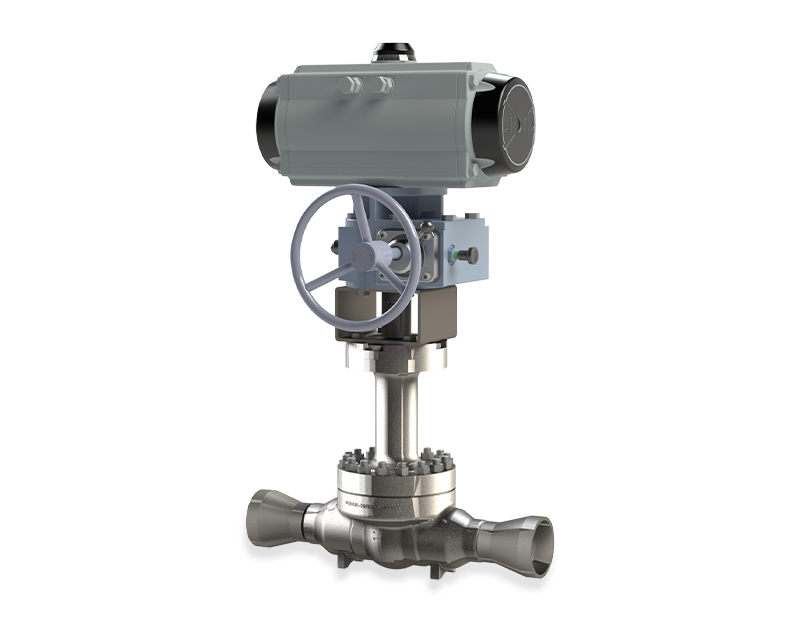

TOP ENTRY BALL VALVE

FOR CRYOGENIC APPLICATIONS

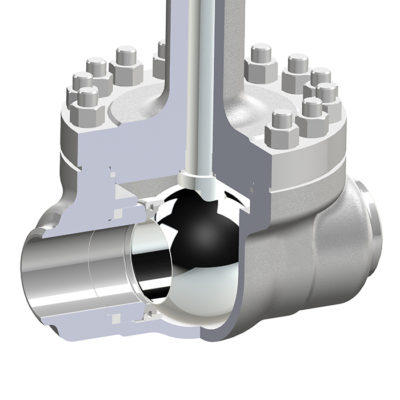

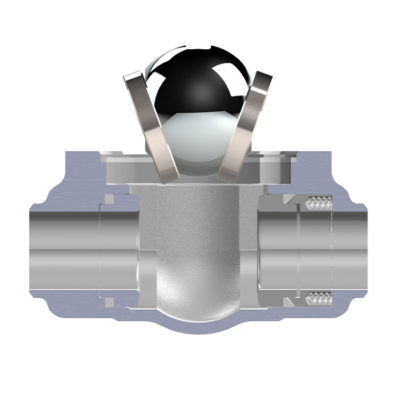

Our Top-Entry Valve can be designed with either floating or trunnion mounted balls.

Due to the stem extension and the chosen seat rings, the ball valve can be used for cryogenic temperatures down to -196°C.

The special seat ring design tolerates the Bi-directional application up to full differential pressure.

FEATURES AND BENEFITS

Assembled Top

Entry Ball Valve

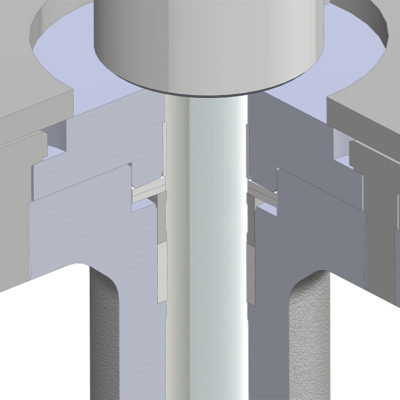

Low Emission

Packing Design

Easy assembling /

disassembling of Ball / Seat unit

Technical data

Advantages

- Easy assembly / disasembly

- Bi-Directional

- Cryogenic test at REMINGTON

- Pressure relieved seating system

- Spring loaded packing

- Blow-out proof

- On-site maintenance (in the plant)

- ISO standard actuator connection

Certification

- Fire Safe according to ISO 10497 / API 607

- Fugitive emission according to ISO 15848-1

| Technical features | |

|---|---|

| Design -ball valve type | 64-K, 66-K oder 67-K |

| Flange connection | Welding ends, flange or according to customer requirements |

| Size | To NPS 16“ / DN 400 |

| PN | Class 1500 / PN 250 |

| Seating system | Soft sealing |

| Temperature range | -196°C to + 100°C |

| Actuation | Manual (lever/gearbox), pneumatic / electric / hydraulic drive |

| Material | |

| Case | DIN 1.4409 / CF3M |

| Ball | DIN 1.4409 / 1.4408 / A 351 CF3M / CF8M |

| Seat rings | PCTFE |

| Seal | Graphite |

| Pack | Graphite |