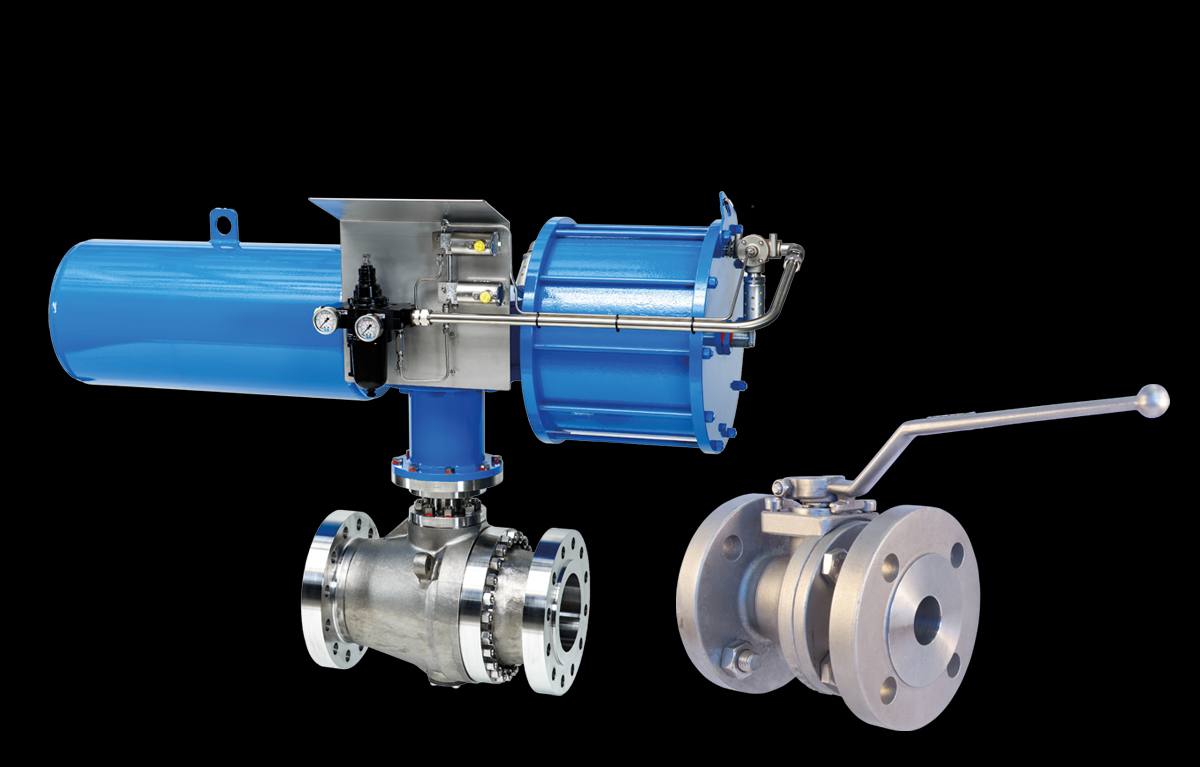

Remington Ball Valves are designed with an emphasis on the requirements of the Chemical and Petrochemical Industries, in addition to those for plant construction. Decades of experience in the Design and Manufacture of Ball Valves, employing ‘State-of-the-Art‘ machinery, forms the basis for the outstanding quality and reliability of the Remington products.

PRODUCT OVERVIEW

‘We develop customized solutions for the widest range of applications for our customers.’

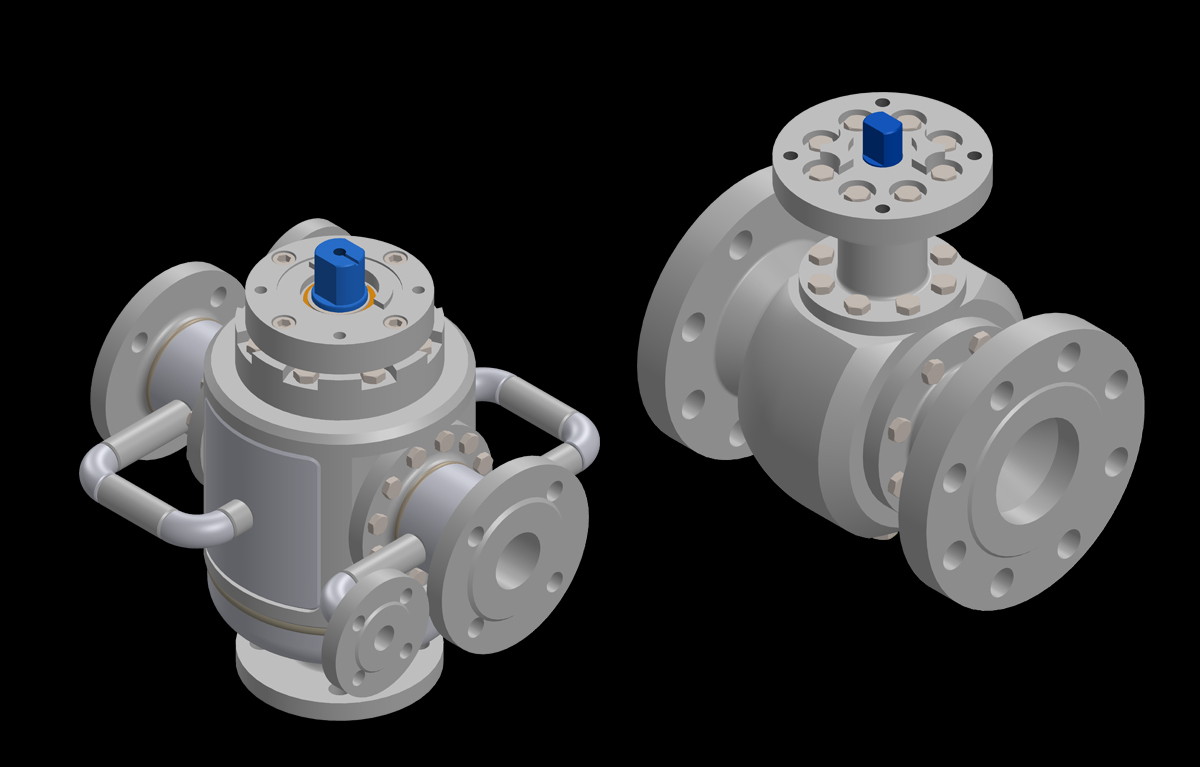

No matter whether it’s special materials, special Ball Valve connectors, flush ports, heating or cooling jackets, high or low-temperature applications, automation or special solutions of any kind: We develop individual customer solutions for a wide range of applications.

The Remington Core products – Metal-Seated Ball Valves – have a High Quality Metal Coating. These Coatings, comprise a variety of ‘Hardfacing‘ materials depending on the respective process / application, are applied / controlled in our ‘in-house‘ Coating facility. The subsequent Machining using ‘State-of-the-Art‘ Grinding and Lapping Technology, ensures outstanding results regarding the Tightness of the Metal Seal of these Ball Valves.

100% INSPECTION –

GUARANTEED QUALITY FOR ALL YOUR APPLICATIONS

Tests and inspections

Automatic test stand for smaller nominal

sizes up to DN 150 / DN 6“

Simultaneous testing of up to 5 Ball

Valves

Visual and electronic recording of results

(bubble count) and evaluation

100 t automatic test stand up to the nominal

size DN 600 / DN 24“

600 t automatic test stand up to the nominal

size DN 600 (24“) to PN 100 (CL 600)

High pressure gas test possible

3-dimensional coordinate measuring machine

for measuring, for example, the roundness of

the balls

PMI (positive material identification), test

device for material identification

Special testing, for example cryogenic-,

fire-safe and helium leak tests

Standard acceptance testing

100% quantity pressure and tightness test

100% quantity strength test at 1.5 x PN

100% quantity functional test

All tests in accordance with international

or customer standards

Visual inspection prior to shippin

-

Automatic test stand for smaller nominal sizes up to DN 150 / DN 6“

-

Simultaneous testing of up to 5 Ball Valves

-

Executive Boar

-

Sales/purchasing

-

Order Management

-

Design and development

-

Quality assurance and planning

-

Warehouse management semi-finished/finished products

-

Ball production/assembly

-

Production of internal components for Metal-Seated Valves